Xiamen JINBEIDE Rubber Science & Technology Co.Ltd, Established in 1991, that is a comprehensive enterprise specialized in Developing, Manufacturing and Exporting all kinds of Rubber,Silicone & Plastic products for use in Engine, Generator, Garden Machinery, Ourdoor Power Equipment, ATV, Motorcycle, Heavy Equipment, Automobile and Aftermarket.

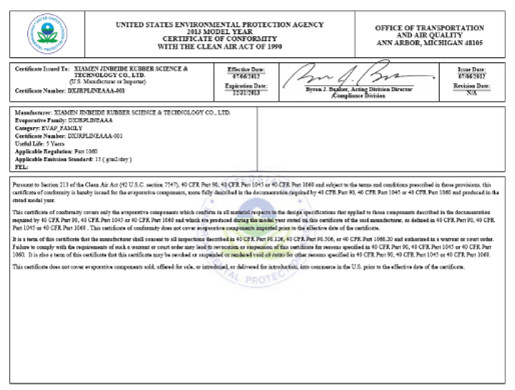

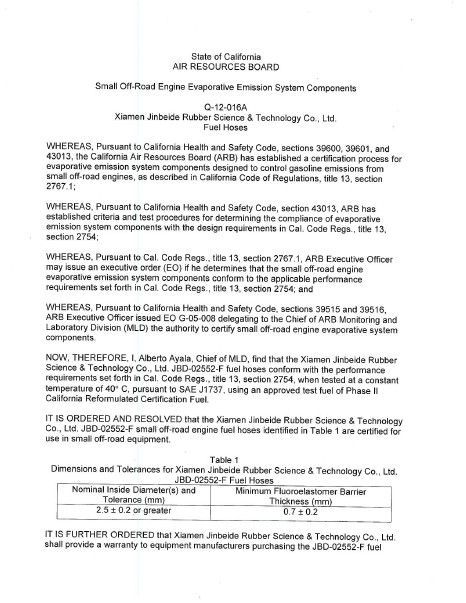

We are the TOP manufacturer of Fuel Line Hose, EPA & CARB certified Fuel Line Hose use in Engine, Generator, ATV, Motorcycle and Garden Machinery,Outdoor Power Equipment,etc.

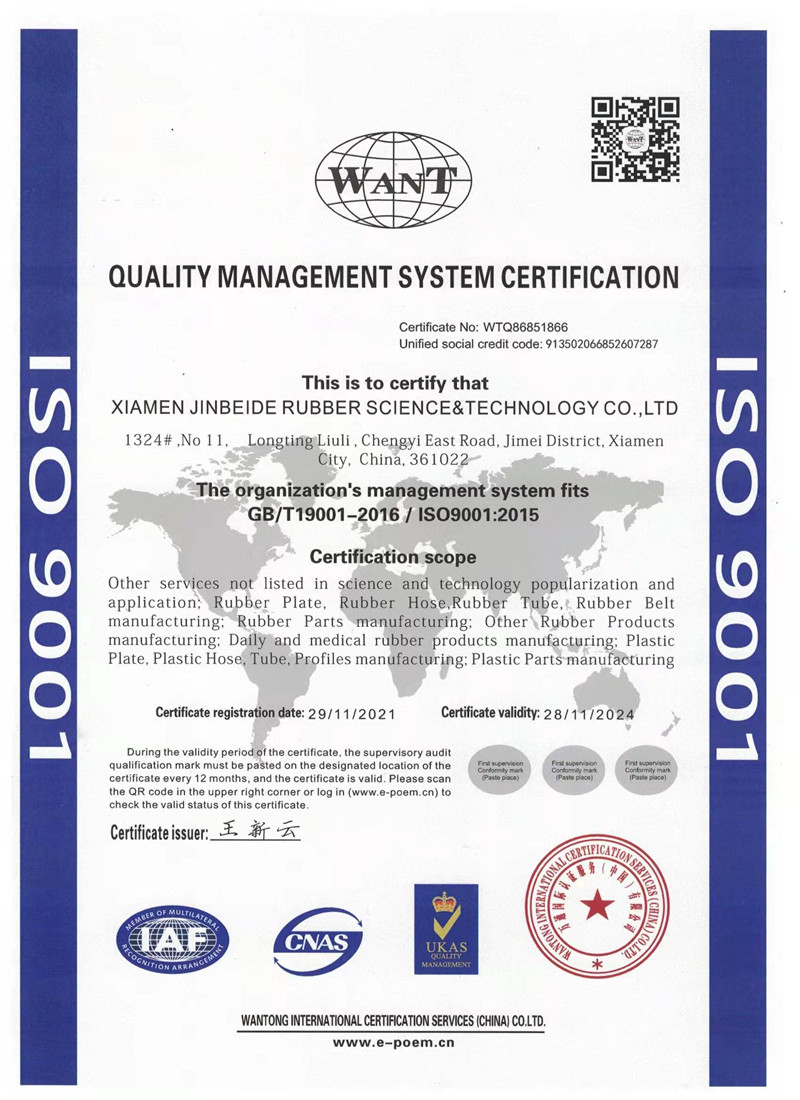

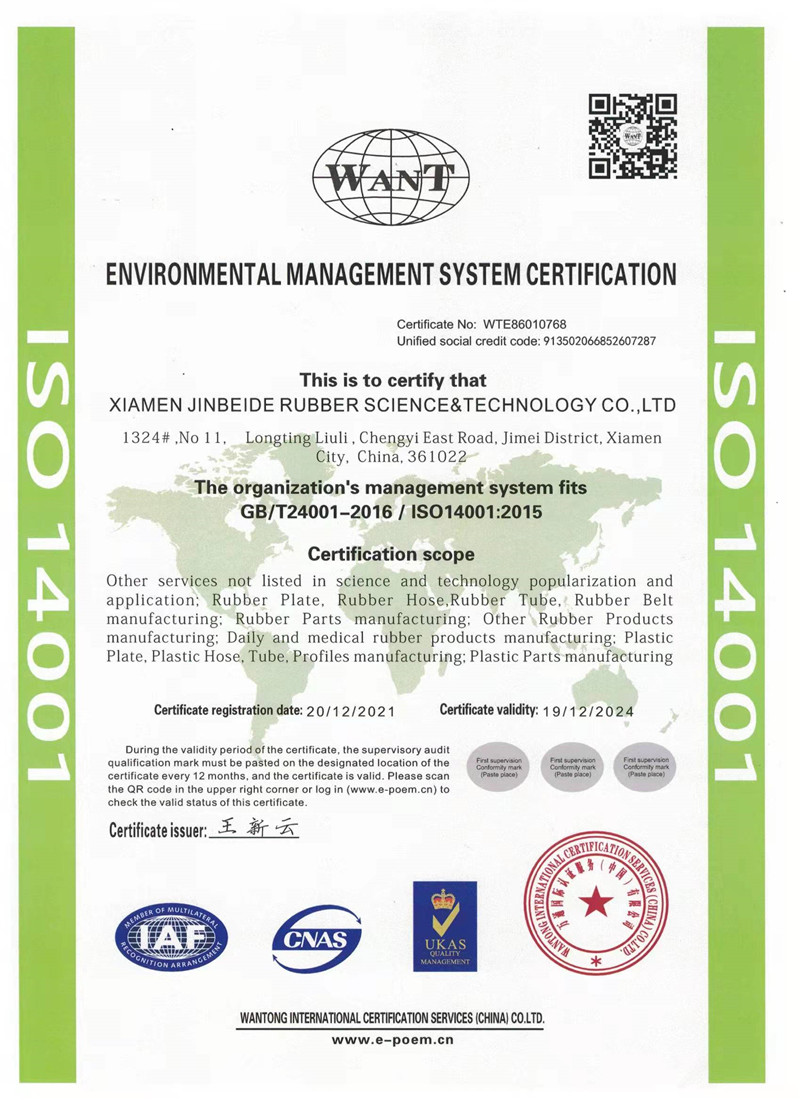

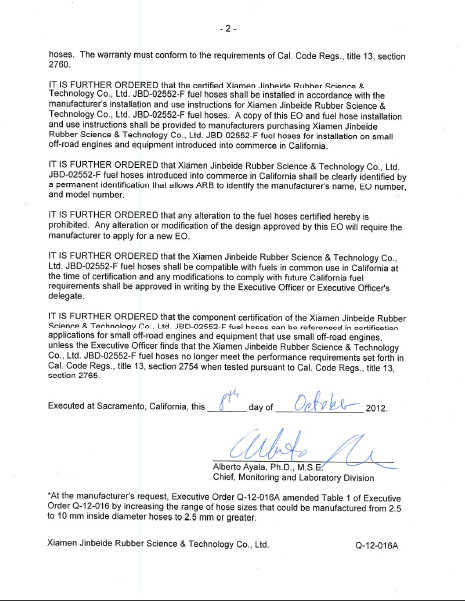

Certificates: Already achieved EPA, CARB, REACH, RoHS, PAHs, NP/OP and Phthalate and passed ISO9001-2008, ISO14001-2004 and TS16949 certificate management system.

Standard: Our products can meet the standard of SAE, HES, EX-S, ASTM and so on

Mission: Better Technology, Better Quality, Better Integrity, and Better Service!

Experience

30+ Years Experienced Technical Teams with Strong R & D Capability.

Base

4 Factories Production Base

ProductionTotal Land Area

Covers An Area Of 185,000 Square Meters

Building Area

1500000 Square Meters

Security

Complete Test Center and Products Laboratory

Passed The ISO9001

& IATF 16949 International Quality System certification

ISO/IATF16949:2016

ISO9001:2015 & ISO14001:2015

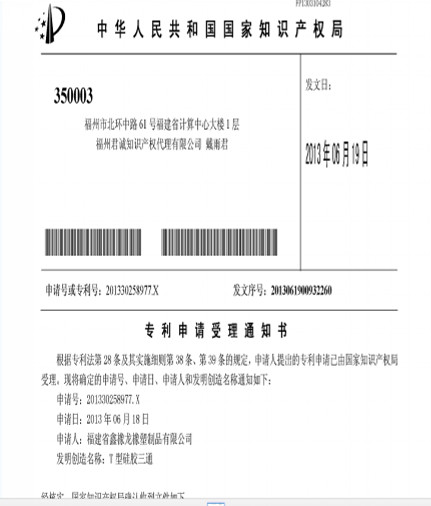

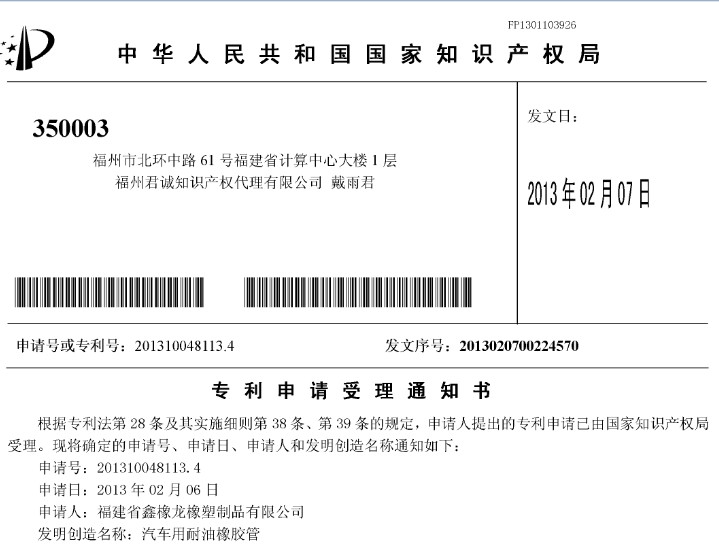

Invention Patents

Honors/Certifications

Achieved the CARB & EPA Certificates in North American Market.

Rubber Mixing Line

The advanced Automatical Production Line have been adopting to increase the production efficiency, that the whole production line can be operated only by 3 people, furthermore to reduce labor cost efficiently. The current capacity is 6000kgs per shift, and it can be up to 18000kgs for 2 shifts per day. We use the advanced air purification equipments to improve the production environment ,that staff’s physical and mental health has been protected efficiently. The Production Lines are in leading position in this industry.

Extruding Line

Coolant Water Hose/Tube Production Line

For this line, we adopts the advanced 90-pin extruder to produce products with Inner Diameter from 6mm to 65mm. The daily Capacity is 3300 meters per shift and is up to 9900 meters per day. The production line is equipped with 5-needles, 10 needles, 14 needles, 16 needles, 20 needles, 28 needles, 32-needles braiding machine that is better than other competitors’ in control the change rate of the hose external diameter . The current rate of external diameter change is ≦ 8%. The service life of the finished products can be improved efficiently. Features: It is a multi-functional production line which is suitable for the production of multi-type of products. It can increase production efficiency greatly.

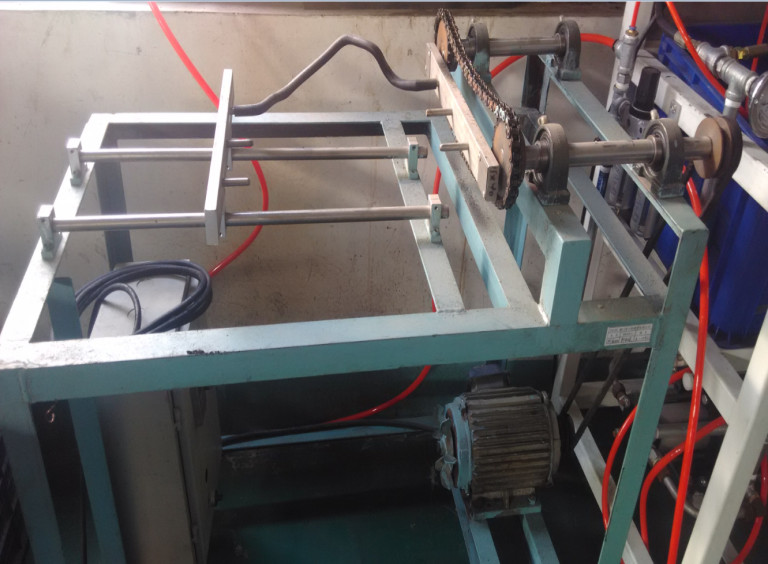

Fuel Hose /Fuel Line Production Line

By adopting the advanced Twin extruder technology, We can produce two layer, three and four layers fuel line hose Features: Twin extruder technology, It is suitable for production of multi-caliber hose with the Inner diameter of from 2.5mm to 50mm

Vulcanization Workshop

By advanced dual-track vulcanization design makes the production capacity of one vulcanizing boiler equals to two. It can save place and also can increase equipment's utilization efficiency. We use industry-leading auto vulcanization control system to control the vulcanization time and pressure strictly and automatically control the intake and exhaust by computer. The manufacturing products can be monitored by vulcanization curve line.

Curing Canister

Molding/Injection

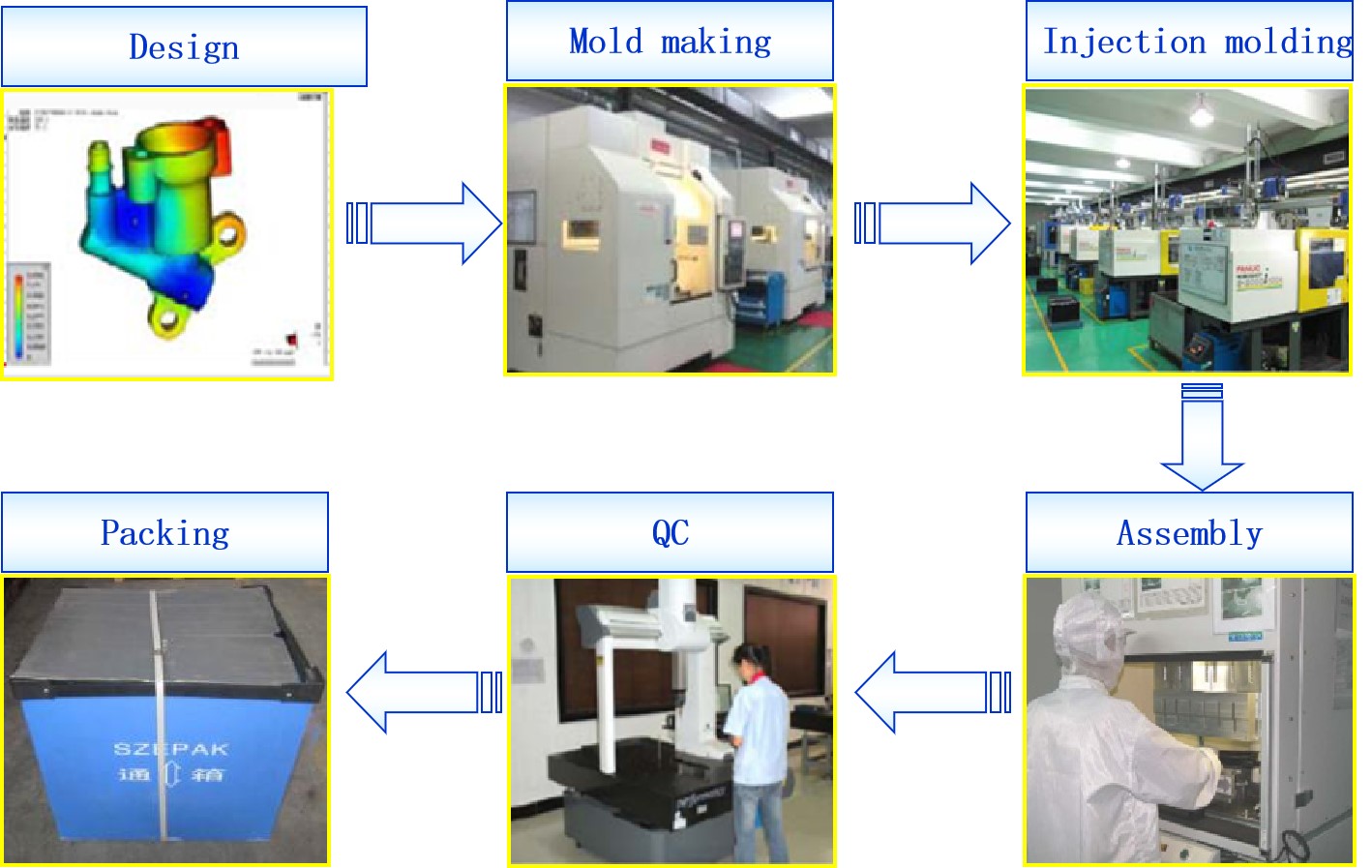

Production Flow( Molding/Injection)

Molded /Injection Machines

Inspection & Package Line

LAB

Testing Equipment

Ozone Resistance Test M/C

Fuel Resistance Test M/C

Leakage Tester

Vibration Fatigue Tester

Electronic Tensile Machine

Heat Aging Oven

Burst Testing Machine

Hardness Tester

Moving Die Rheometer

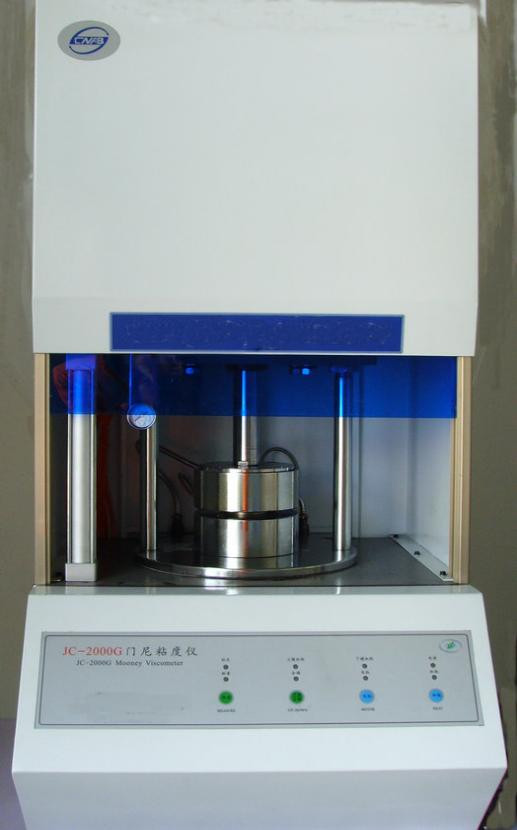

Mooney Viscometer

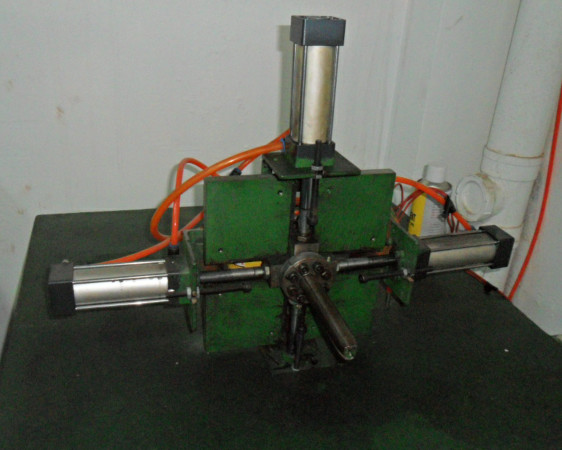

Punch Machine

Thickness Tester

Open Type Mixing Machine

Precision Electronic Hydrometer

Vacuum Tester

Expanded Tester

Cold Resistance Test M/C