EPA/CARB Certified Rubber Fuel Line

| Product: | EPA/CARB Certified Rubber Fuel Line |

| Item No.: | JBD-A001 |

| Size & Shape: | ID≥Φ2.5 mm; Customized as Required. |

| Material: | FKM; FKM/ECO; FKM/ECO/AR/ECO |

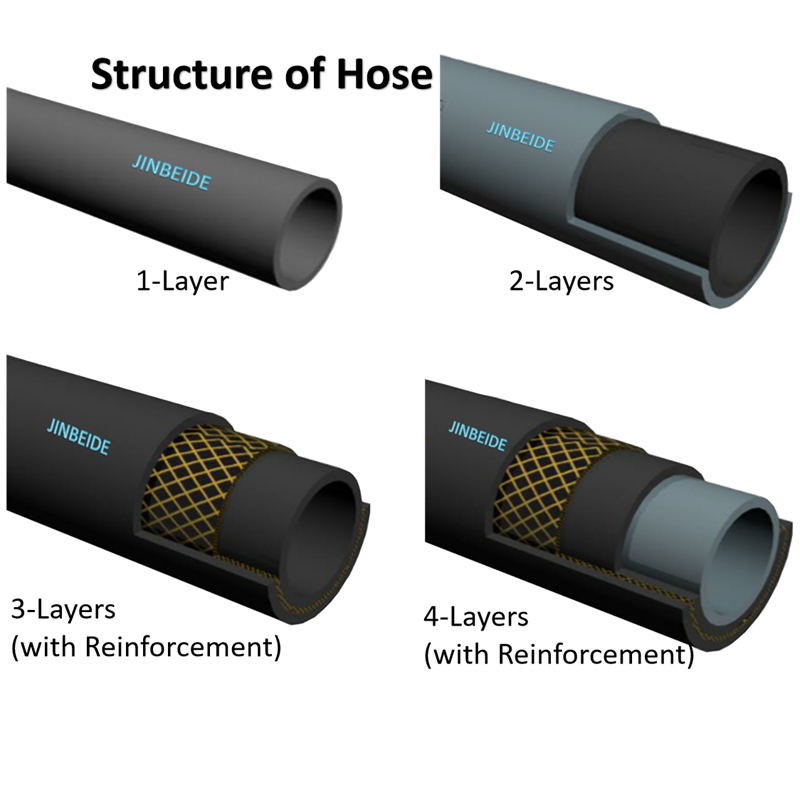

| Structure: | 1 to 4-layers |

| Color: | Black |

| Application | use for All-Terrain Vehicle ( ATVs), Motorcycle, Snowmobiles,Automobiles, Engines, Outdoor Power Equipments, Garden Machinery, Lawn Mower, Chainsaw, Trimmer, Off-Road Engines, Marine Engines (Inboard & Outboard Marine Engines ), Small Engines and Generators. |

| EPA & CARB CERTIFICATE | YES. |

| Standard | SAE, YDK,HES, EX-S,ASTM and so on |

| Shipping Port | Xiamen |

| OEM/ODM | Accepted |

| Package | PE bag+Carton+Pallet |

| Payment Terms | T/T, L/C,Western Union |

| Factory | ISO/IATF16949:2009 registered |

| Technical Teams | 30+ Years experience |

| Sample Leadtime | 7-15 days |

| Production Leadtime | 20-30 days |

RUBBER TEST METHODS & SPECIFICATIONS

| RUBBER TEST METHODS & SPECIFICATIONS | Unit | Value | |||

| EXTRACTABLES | ASTM FULE C,300MM LONG SPECIMENS METHODS CONFORM TO 6.5.8 |

g/m2 | 2.50 MAX | ||

| PERMEATION | ASTM FULE C, METHODS CONFORM TO 9.1~9.2 |

g/m2/24H | 15 MAX | ||

| BURST | HOSE ID < 9.53mm | MPA | 6.2 MIN | ||

| HOSE ID > 9.53mm | MPA | 3.4 MIN | |||

| VACUUM COLLAPSE | DURING APPLICATION OF VACUUM FOR A MINIMUM OF 15S AND NOT MORE THAN 60S | % | 20 MAX | ||

| COLD FLEXIBILITY | TO BE DRY HEAT AGED FOR 135℃×70H,AFTER AGING,TO BE CONDITIONED AT -34℃×5H,THEN FLEXED IN THE COLD CHAMBER THROUGH 180 DEGREES FROM THE CNETERLINE TO A DIAMETER OF 10 TIMES THE MAXIMUM OD OF THE HOSE | NOT FRACTURE, NO CRACKS, NOCHEKS, NO BREAKS |

|||

| OZONE RESISTANCE | SHALL BE ACCORDANCE WITH ASTM D 1149, THE SPECIMEN SHALL BE ALLOWED TO REST IN AN OZONE-FREE FOR 23℃×24H ,AND THE MOUNTED SPECIMEN SHALL BE PLACED IN A TEST CHAMBER CONTAINING OZONE AT 100MPA×40℃,AFTER 70H OF EXPOSURE | NO CRACKS (BE VISUALLY INSPECTED UNDER 7X MAGNIFICATION) |

|||

| ADHESION | SEPARATE A 25.4MM WIDTH | N | 35.6 MIN | ||

| KINK RESISTANCE | 300MM LONG SPECIMEN,23℃×2H,BEND HOSE ALONG ITS NATURAL CURVATURE AND INSERT THE OTHER END CAREFULLY INTO THE SECOND HOLE UNTIL IT PROJECTS 63 MM OUT THE OTHER SIDE | PASS | |||

| DRY HEAT RESISTANCE | THE HOSE TO SLOWLY STRAIGHTENED(TAKING 7 TO 8S)AFTER BEING EXPOSED AS SHOWN IN FIGURE FOR A PERIOD OF 7 DAYS FOR 150 ℃ | NO CRACKS, NO CHARRING, NO DISINTEGRATION |

|||

| RUBBER TEST METHODS & SPECIFICATIONS | Unit | Value | |||

| ORIGINAL STATE (TUBE) |

ROOM TEMP | TENSILE STREGTH | MPA | 5. 0 MIN | |

| ELONGATION | % | 125 MIN | |||

| ORIGINAL STATE (COVER) |

ROOM TEMP | TENSILE STREGTH | MPA | 8. 0 MIN | |

| ELONGATION | % | 150 MIN | |||

| OIL RESISTANCE ASTM NO. 3 (COVER) |

150℃×70H METHODS CONFORM TO ASTM D471 |

TENSILE CHANGE | % | +100 MAX | |

| FUEL RESISTANCE FUEL C (TUBE) |

23℃×48H METHODS CONFORM TO ASTM D471 |

VOLUME CHANGE | % | +10 MAX | |

| ETHANOL MODIFIED FUEL RESISTANC (85% FUEL D 15% ETHANOL) TUBE |

23℃×70H METHODS CONFORM TO ASTM D471 |

VOLUME CHANGE | % | 0~+15 | |

| TENSILE CHANGE | % | -40 MAX | |||

| ELONGATION CHANGE | % | -40 MAX | |||

| OXIDIZED FUEL (TUBE) |

FULE “B”,ACORRDING TO 6.5.14 | TENSILE CHANGE | % | -30 MAX | |

| ELONGATION CHANGE | % | -20 MAX | |||

OEM & ODM

The EPA & CARB Certificated Rubber Fuel Line can be acceptable OEM & OEM as per client’s drawings ,samples and other requirements, meeting the Low Permeation requirement according to the Standard of SAE, YDK,HES, EX-S,ASTM,

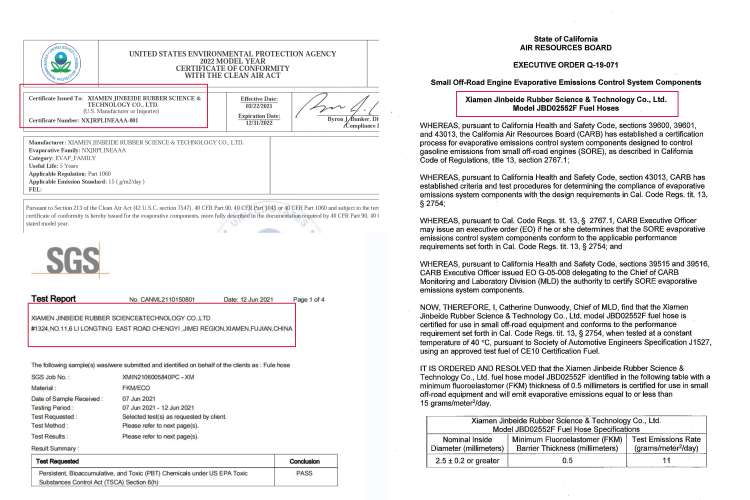

EPA & CARB CERTIFICATE

The EPA/CARB Certified Rubber Fuel Hose is achieved the EPA & CARB Certificate according the requirements of Low Permeation at Max 15 g/m2/day in North American Markets.

Application

The EPA/CARB Certificated Rubber Fuel Line is widely use for All-Terrain Vehicle ( ATV), Motorcycle, Snowmobiles,Automobiles, Engines, Outdoor Power Equipments, Garden Machinery, Lawn Mower, Chainsaw, Trimmer, Off-Road Engines, Marine Engines (Inboard & Outboard Marine Engines ), Small Engines and Generators.

Our Uniquie Advantages:

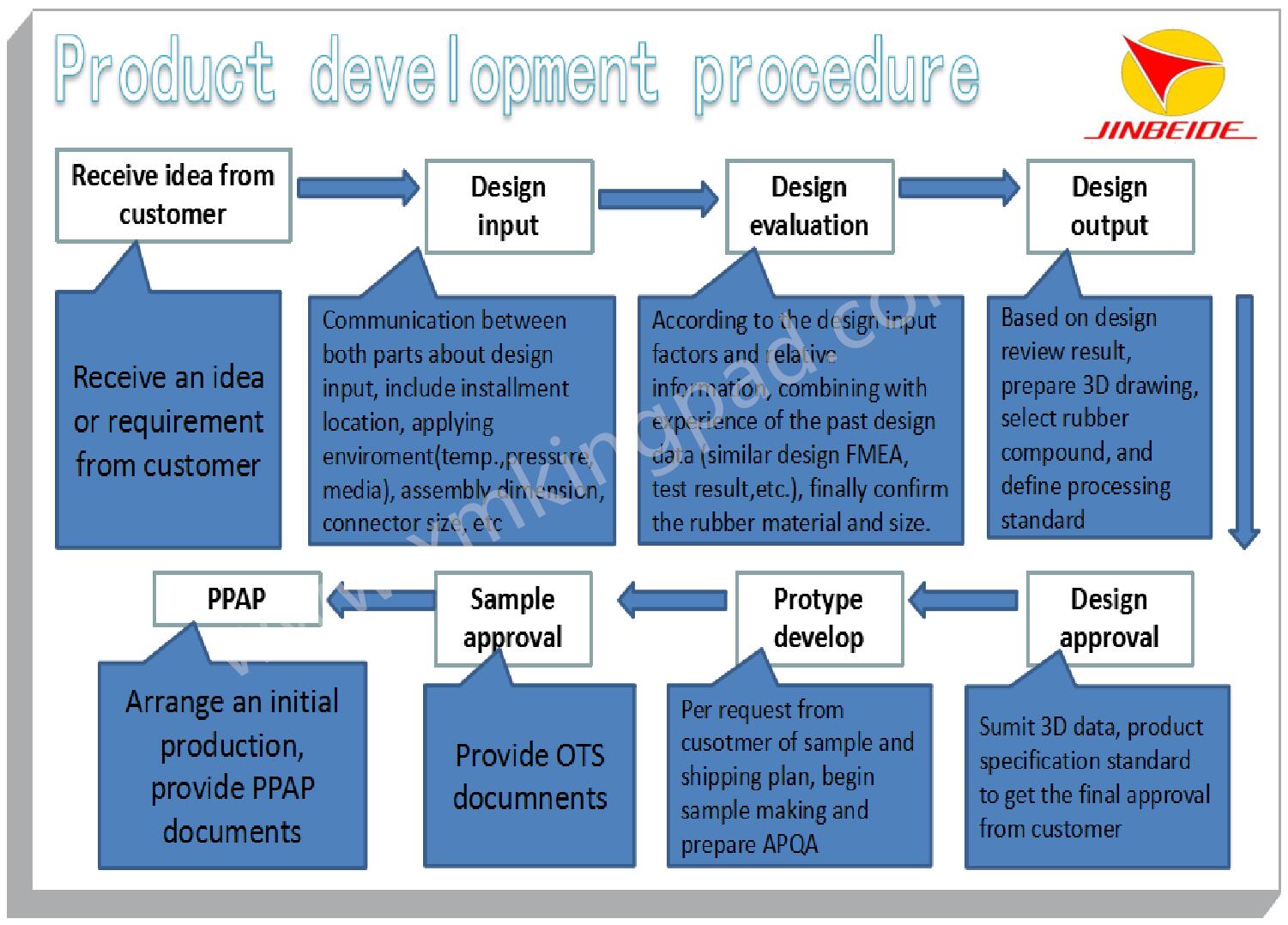

A: 30+ Years Experienced Professional Technical Teams with strong R&D Center.

B: Powerful Capacity with 4 Factories Production Base.

C: Stable Quality and Competitive Price—-We are an integrated company combining Rubber Raw Materials Refining & Mixer Process and manufacturing Rubber products with professional Technics, as well as Rubber Raw Materials Wholesales.

D: Delivery time—-20-30 days for mass production.

Structure of Hose

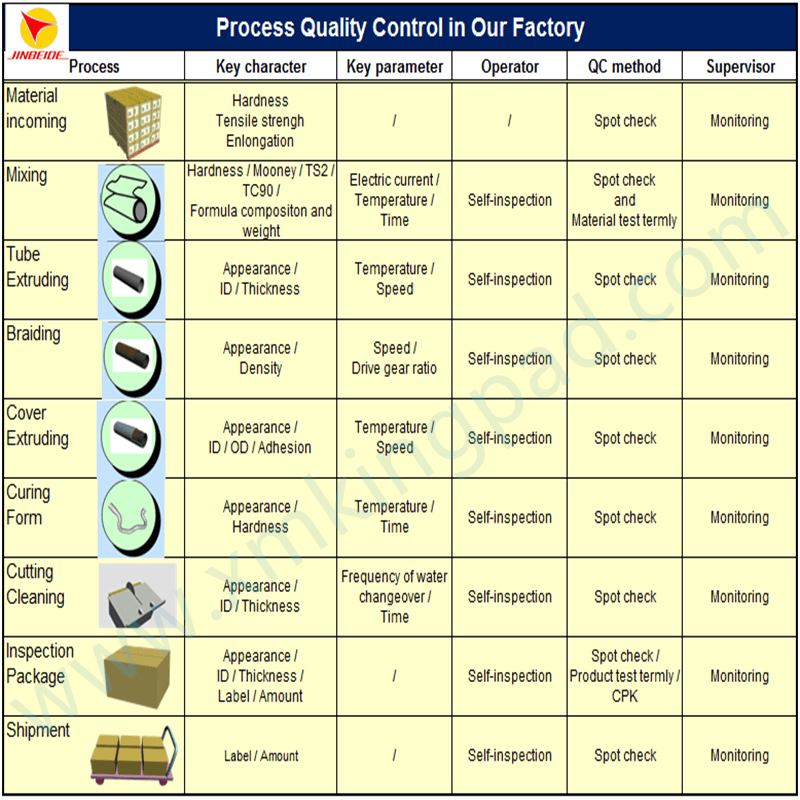

Process Of Quality Control

Process of Product Development

Products Collect

Packaging & Shipping