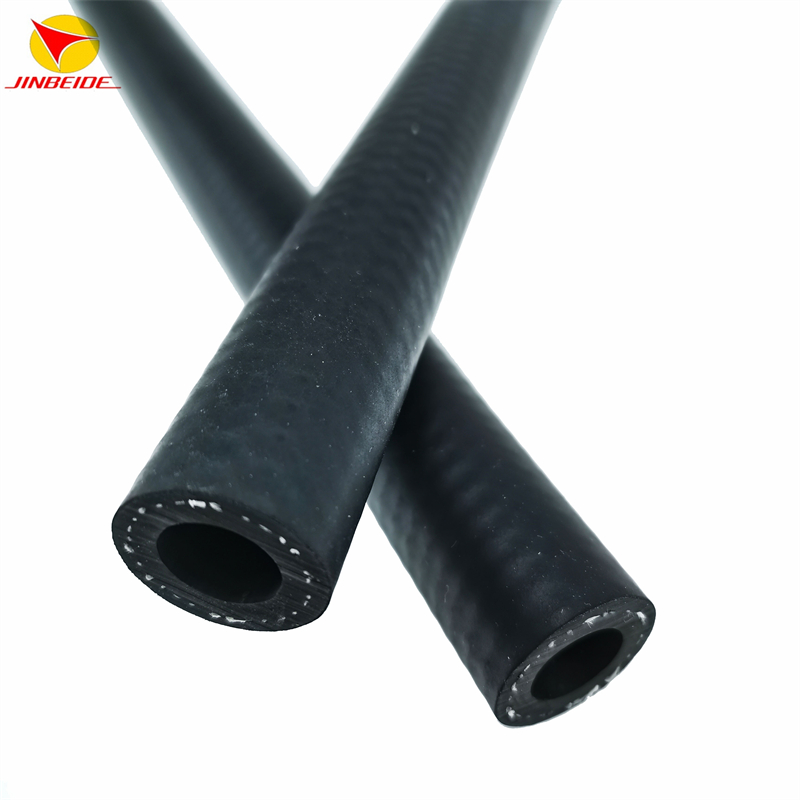

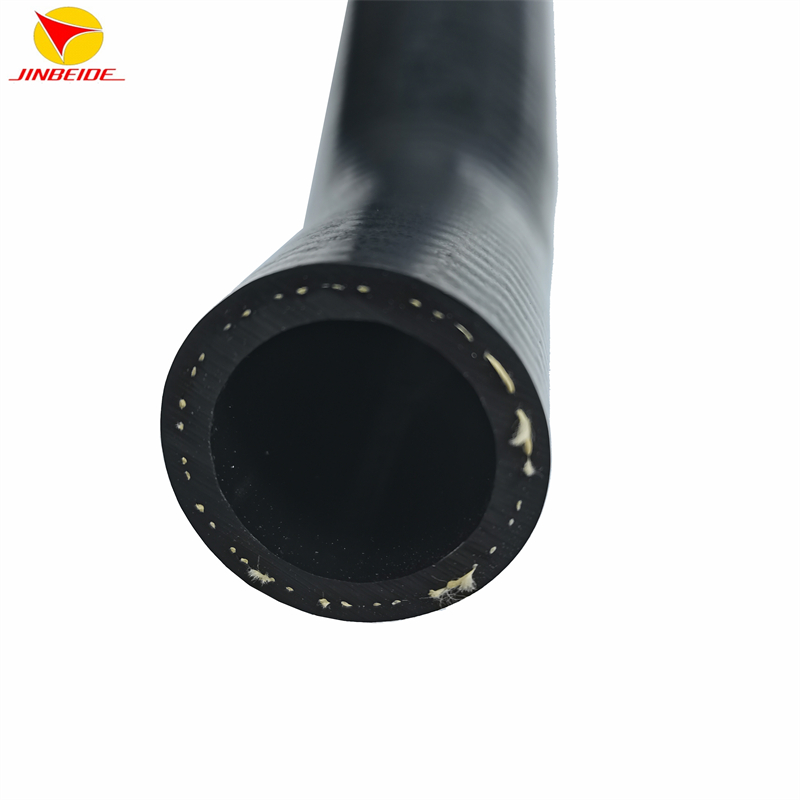

Customized EPDM Reinforcement Radiator Coolant Hose for Cooling System

| Product: | Customized EPDM Reinforcement Radiator Coolant Hose for Cooling System |

| Item No.: | JBD-D010 |

| Size & Shape: | ID≥Φ2 mm; Customized as Required. |

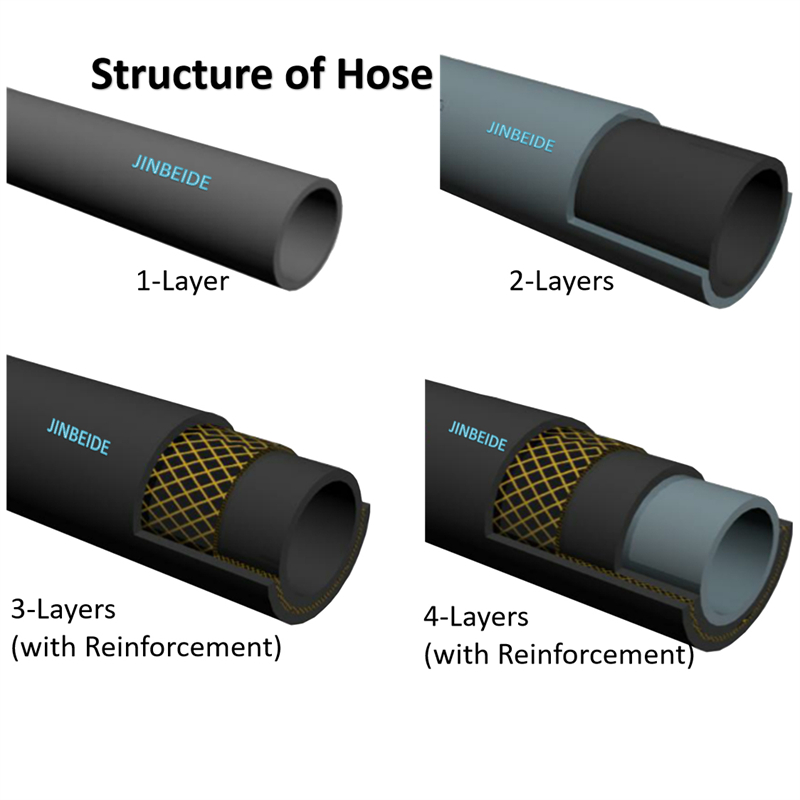

| Material: | EPDM; EPDM/EPDM; EPDM/YARN/EPDM |

| Structure: | 1-3 Layers |

| Color: | Black |

| Standard | SAE, YDK,HES, EX-S,ASTM and so on |

| Application | use in Cooling System in Automobile, Trucks,Motorcycle,ATV,Engines,Outdoor Power Equipments,Electrical Machines, etc. |

| Shipping Port | Xiamen |

| OEM/ODM | Accepted |

| Package | PE bag+Carton+Pallet |

| Payment Terms | T/T, L/C,Western Union |

| Factory | ISO/IATF16949 registered |

| Technical Teams | 30+ Years experience |

| Sample Leadtime | 7-15 days |

| Production Leadtime | 20-30 days |

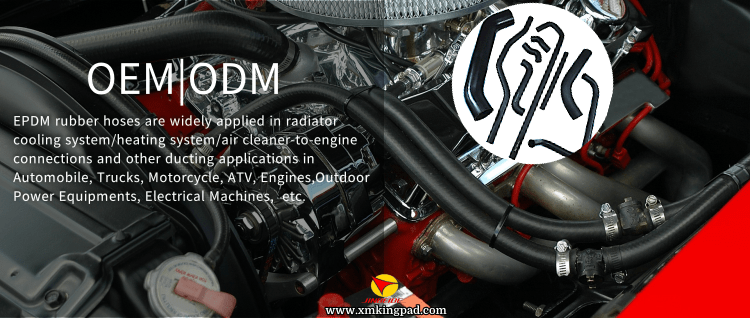

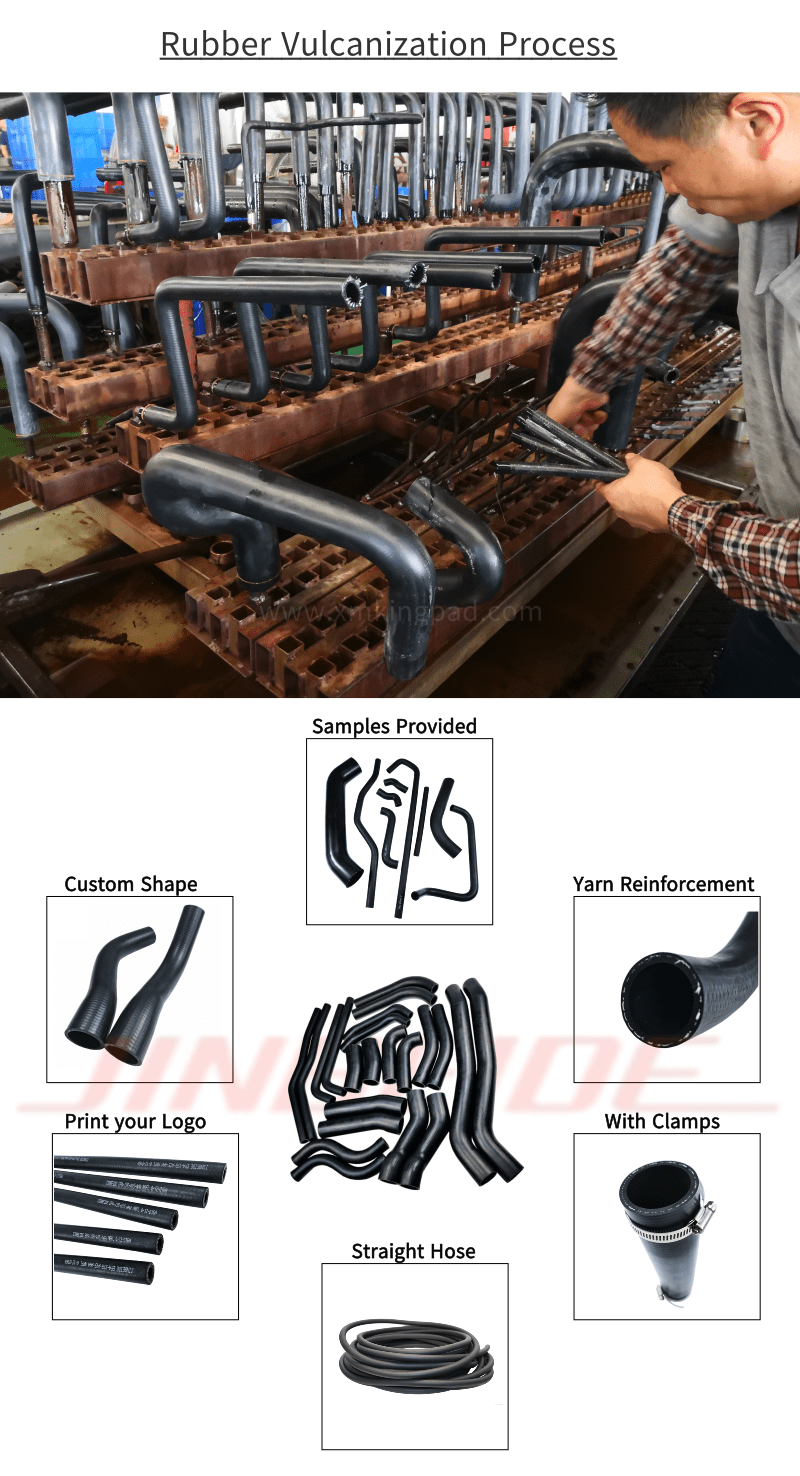

OEM & ODM

Customized EPDM Reinforcement Radiator Coolant Hose for Cooling System can be accepted OEM & OEM as per client’s drawings ,samples and other specifications, meeting the requirement according to the Standard of SAE, YDK,HES, EX-S,ASTM, and so on.

APPLICATION

Customized EPDM Reinforcement Radiator Coolant Hose for Cooling System widely use in Radiator Cooling System/heating system/air cleaner-to-engines connections and other water application in Automobiles, Trucks, All-Terrain Vehicle ( ATVs), Motorcycle, Snowmobiles,Engines, Outdoor Power Equipments, and Generators.

| ■ Material Property Test | Test Standard: | SAE J20 R4 D1 | ||||

| ■ Product Property Test | ||||||

| Material: | EPDM COOLANT HOSE | |||||

| Testing Items (JBD) (SAE J20 R4 D1) |

JBD Test Condition (SAE J20 R4 D1) |

Test Content | Unit | JBD Basic Value |

||

| ORIGINAL STATE | ROOM TEMP | HARDNESS | HS | 55 to 75 | |

| TENSILE STRENGTH |

Mpa | 7.0 MIN | |||

| ELONGATION | % | 250 MIN | |||

| HEAT AGING | 125℃*72h | HARDNESS CHANGE |

HS | +15 MAX | |

| TENSILE STRENGTH |

% | -20 MAX | |||

| ELONGATION | % | -50 MAX | |||

| COOLANT IMMERSION | Boiling Point*72h | HARDNESS CHANGE |

HS | -10~+10 | |

| TENSILE STRENGTH |

% | -20 MAX | |||

| ELONGATION CHANGE |

% | -50 MAX | |||

| VOLUME CHANGE |

% | -5~+20 | |||

| COMPRESSION | 125℃*72h | COMPRESSION SET |

% | 75 MAX | |

| COLD FLEXIBILITY | -40℃×5h,Flexed 180 degrees ×10time | NO CRACKS | |||

Our Uniquie Advantages:

A: 30+ Years Experienced Professional Technical Teams with strong R&D Center.

B: Powerful Capacity with 4 Factories Production Base.

C: Stable Quality and Competitive Price----We are an integrated company combining Rubber Raw Materials Refining & Mixer Process and manufacturing Rubber products with professional Technics, as well as Rubber Raw Materials Wholesales.

D: Good & In Time Service----all the enquiry will be processed within 24 hours with satisfactory service before and after sale.

E: Delivery time----15-20 days for mass production.

Yes, our products achieve EPA& CARB Certificates.

Yes, all of our products are green products meet RoHS, REACH.

Yes, OEM/ODM can be acceptable.

Most of our products are customized and manufactured as per client’s Drawings and Requirements.

Yes, PPAP’s is a basic documents under our IATF16949 certificate.

T/T and L/C is acceptable . 30% downpayment and balance before shipments by T/T. Or 100% irrevocable LC at sight.

Yes, we always use high quality export packaging. We also use specialized hazard packing for dangerous goods and validated cold storage shippers for temperature sensitive items. Specialist packaging and non-standard packing requirements may incur an additional charge.