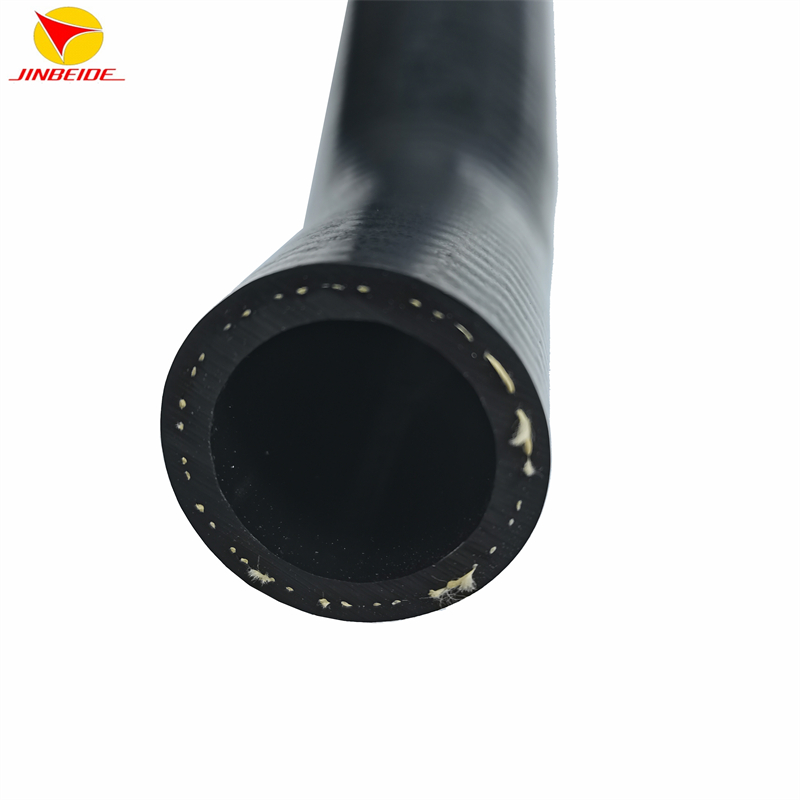

EPDM Reinforcement Hose Automotive Radiator Coolant Hose for Cooling System

| Product: | EPDM Reinforcement Hose Automotive Radiator Coolant Hose for Cooling System |

| Item No.: | JBD-D013 |

| Size & Shape: | ID≥Φ2 mm; Customized as Required. |

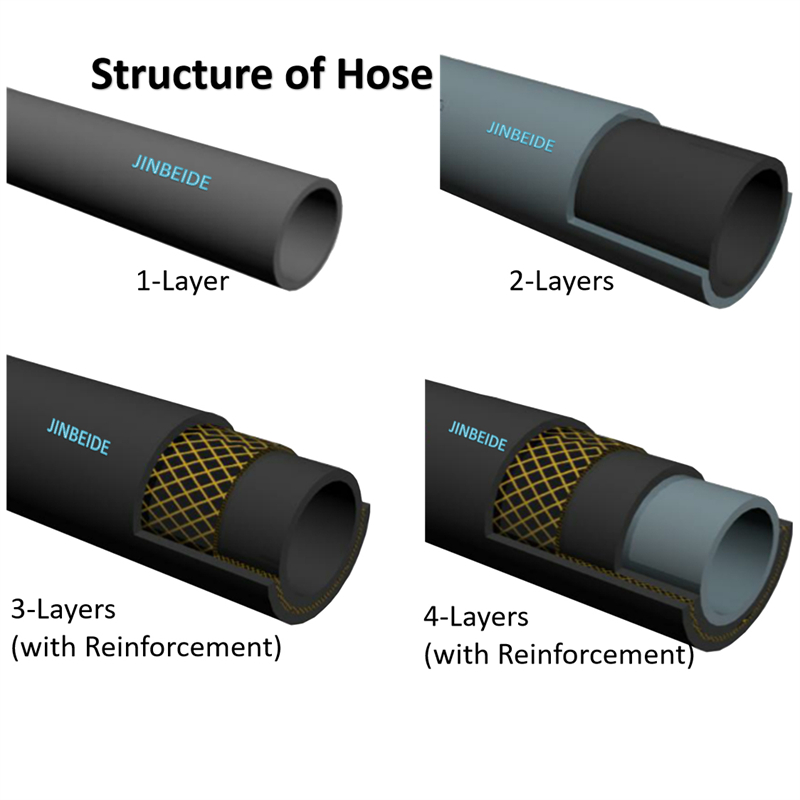

| Material: | EPDM; EPDM/EPDM; EPDM/YARN/EPDM |

| Structure: | 1-3 Layers |

| Color: | Black |

| Standard | SAE, YDK,HES, EX-S,ASTM and so on |

| Application | use in Cooling System in Automobiles. |

| Shipping Port | Xiamen |

| OEM/ODM | Accepted |

| Package | PE bag+Carton+Pallet |

| Payment Terms | T/T, L/C,Western Union |

| Factory | ISO/IATF16949 registered |

| Technical Teams | 30+ Years experience |

| Sample Leadtime | 7-15 days |

| Production Leadtime | 20-30 days |

OEM & ODM

EPDM Reinforcement Hose Automotive Radiator Coolant Hose for Cooling System can be accepted OEM & OEM as per client’s drawings ,samples and other specifications, meeting the requirement according to the Standard of SAE, YDK,HES, EX-S,ASTM,

SPECIFICATION

| RUBBER TEST METHODS & SPECIFICATIONS | |||||

| ORIGINAL STATE | ROOM TEMP | HARDNESS | HS | 55 to 75 | |

| TENSILE STRENGTH |

Mpa | 7.0 MIN | |||

| ELONGATION | % | 250 MIN | |||

| HEAT AGING | 125℃*72h | HARDNESS CHANGE |

HS | +15 MAX | |

| TENSILE STRENGTH |

% | -20 MAX | |||

| ELONGATION | % | -50 MAX | |||

| COOLANT IMMERSION | Boiling Point*72h | HARDNESS CHANGE |

HS | -10~+10 | |

| TENSILE STRENGTH |

% | -20 MAX | |||

| ELONGATION CHANGE |

% | -50 MAX | |||

| VOLUME CHANGE |

% | -5~+20 | |||

| COMPRESSION | 125℃*72h | COMPRESSION SET |

% | 75 MAX | |

| COLD FLEXIBILITY | -40℃×5h,Flexed 180 degrees ×10time | NO CRACKS | |||

APPLICATION

EPDM Reinforcement Hose Automotive Radiator Coolant Hose for Cooling System widely use in Radiator Cooling System/heating system/air cleaner-to-engines connections and other water application in Automobiles.

Our Uniquie Advantages:

A: 30+ Years Experienced Professional Technical Teams with strong R&D Center.

B: Powerful Capacity with 4 Factories Production Base.

C: Stable Quality and Competitive Price—-We are an integrated company combining Rubber Raw Materials Refining & Mixer Process and manufacturing Rubber products with professional Technics, as well as Rubber Raw Materials Wholesales.

D: Delivery time—-20-30 days for mass production.

E: Do you provide PPAP’s ? --Yes, PPAP’s is a basic documents under our IATF16949 certificate.

F: Various Material dealing with--Our main Rubber & Plastic materials are NBR,SBR,NR,ACM,AEM,CSM,ECO,FKM,VMQ, EPDM,SILICONE,PVC,TPU,ect

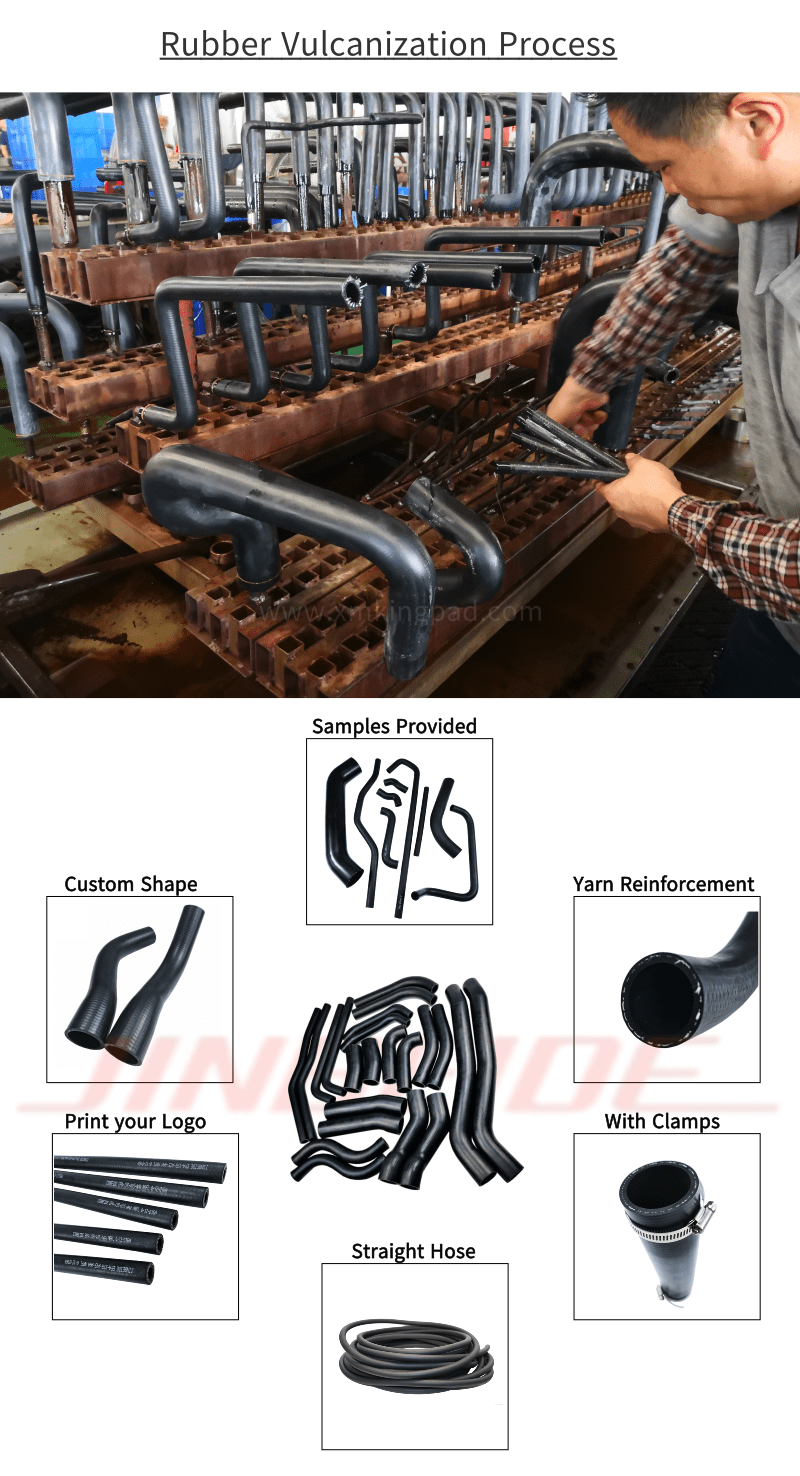

Structure of Hose

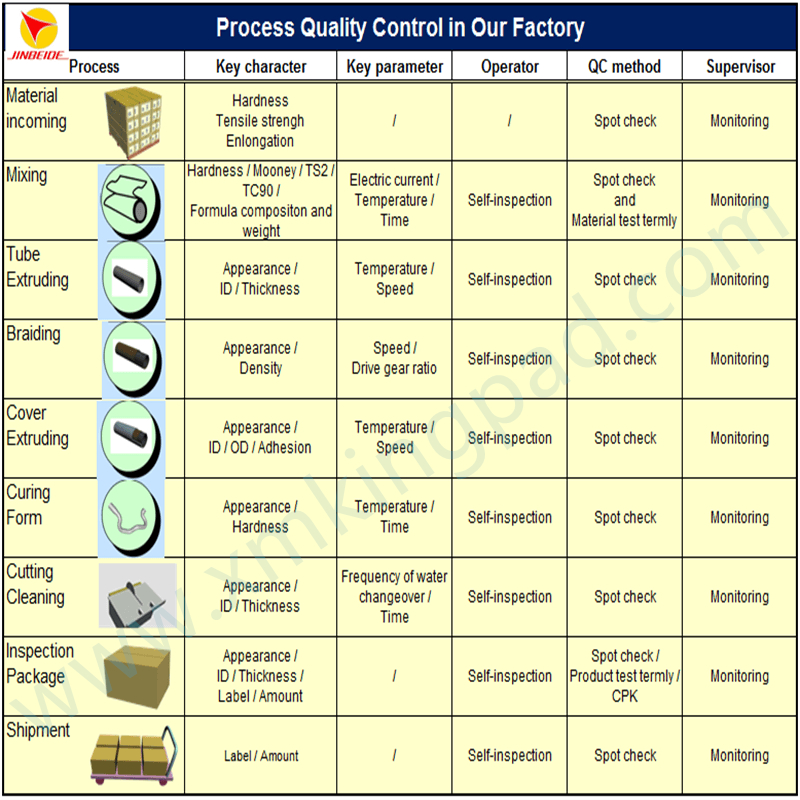

Process Of Quality Control

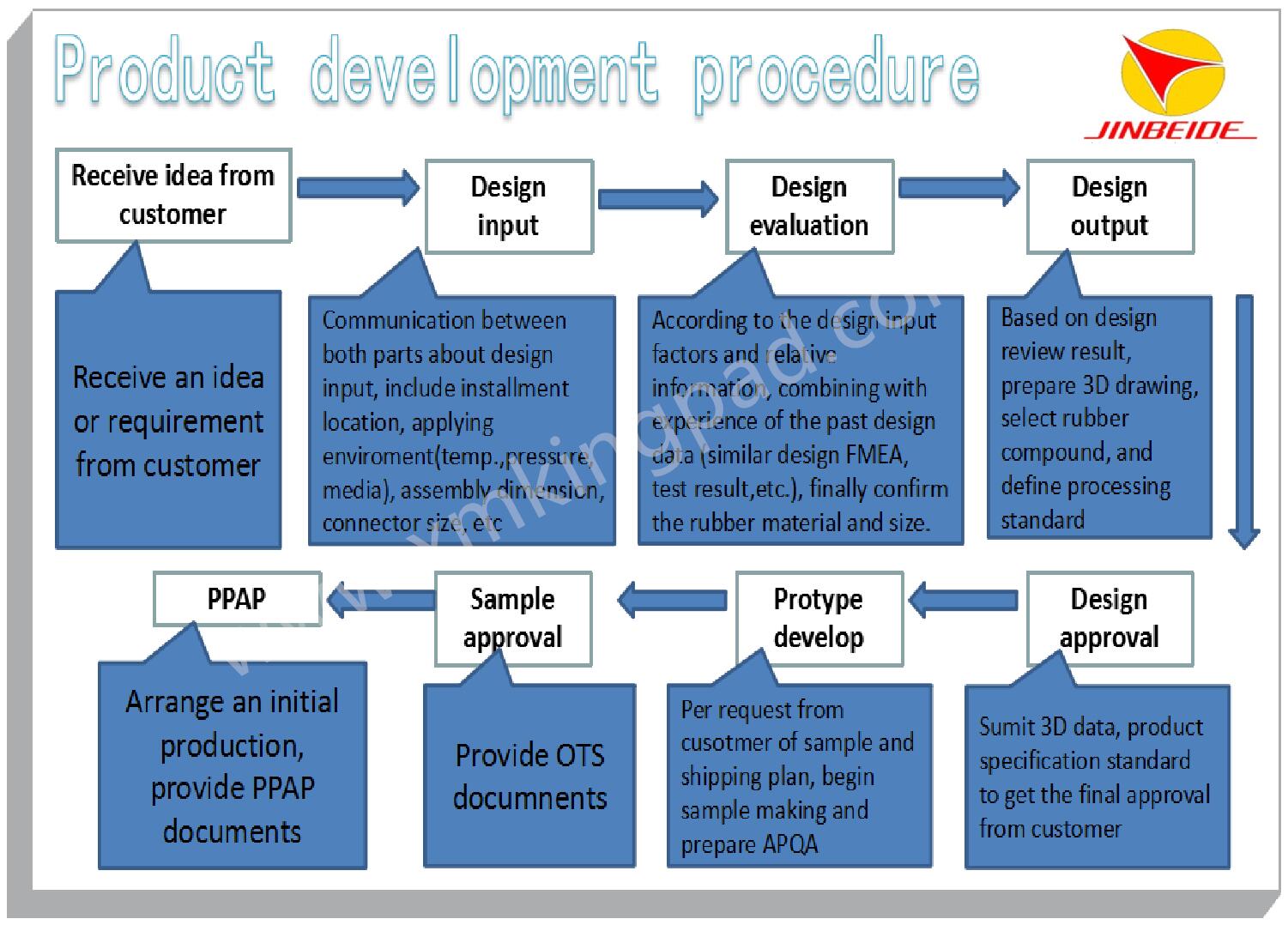

Process of Product Development

Products Collect

Packaging & Shipping