Custom Different Size Flexible Oil Heat & Acid Resistan FKM Oil Hose Fuel Tube

| Product: | Custom Different Size Flexible Oil Heat & Acid Resistan FKM Oil Hose Fuel Tube |

| Item No.: | JBD-E037 |

| Size & Shape: | ID≥Φ2.5 mm; Customized as Required. |

| Material: | FKM/ECO; FKM/YARN/ECO |

| Color: | Black |

| Application | Use for Fuel Supply system in Automobiles, Motorcycles.ATV,Garden Machinery,Engines,Generators and so on |

| Standard | SAE, YDK,HES, EX-S,ASTM and so on |

| Shipping Port | Xiamen |

| OEM/ODM | Accepted |

| Package | PE bag+Carton+Pallet |

| Payment Terms | T/T, L/C,Western Union |

| Factory | ISO/IATF16949 registered |

| Technical Teams | 30+ Years experience |

| Sample Leadtime | 7-15 days |

| Production Leadtime | 20-30 days |

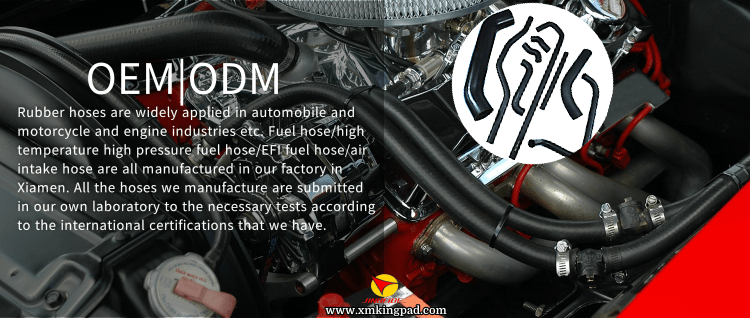

OEM & ODM

Custom Different Size Flexible Oil Heat & Acid Resistan FKM Oil Hose Fuel Tube can be accepted OEM & OEM as per client’s drawings ,samples and other specifications,are widely applied in automobile and motocycle and engine, Fuel Hose, High Temperature & High Pressure Fuel Hose, EFI Fuel Hose are all manufactured in our factory. All the hoses we manufactured are submitted in our laboratory to the necessary tests and meet the Standard of SAE, YDK,HES, EX-S,ASTM and so on,

APPLICATION

Custom Different Size Flexible Oil Heat & Acid Resistan FKM Oil Hose Fuel Tube widely Use for Fuel Supply System in Automobiles, Motorcycles, ATV, Garden Machinery, Engines, Generators and so on.

SPECIFICATON

| Test Condition and Result | ||||||||||

| NO | Item | Test Condition | Basic Value | Test Value | Judge | |||||

| 1 | Burst test | Test burst pressure | ≥6.2MPa | 7MPa | OK | |||||

| 2 | Vacuum Collapse Test | 一81KPa ,15-60 seconds | OD Changing Rate,Max:-20% | -6.5% | OK | |||||

| 12 | Ethanol fuel resistance test | To be immersed in 85%FUEL D+15% absolute ethyl alcohol RT *70Hr | Inner Layer: change rate of tensile strengthMax -40% ; | -20% | OK | |||||

| Inner Layer:Change rate in elongation:Max -40%; | -28% | OK | ||||||||

| Inner Layer:Chang rate of Volume: Max 0-15% | 7% | OK | ||||||||

| 13 | OXIDIZED FUEL TEST | —Cut three tensile (D471 C#) specimens to immerse in 200ml mixture consisting of 3600 mL of ASTM Fuel "B" and 10 mL of 90% t-butyl hydroperoxide for 40℃*14 days | Inner Layer: change rate of tensile strengthMax -30% ; | -15% | OK | |||||

| Inner Layer:Change rate in elongation:Max -20%; | -12% | OK | ||||||||

| 14 | Low Permeation test | ASTM FULE C, METHODS CONFORM TO 9.1~9.2 and EPA Regulation |

≤15g/m2/day | 10.2 | OK | |||||

Our Uniquie Advantages:

A: 30+ Years Experienced Professional Technical Teams with strong R&D Center.

B: Powerful Capacity with 4 Factories Production Base.

C: Stable Quality and Competitive Price—-We are an integrated company combining Rubber Raw Materials Refining & Mixer Process and manufacturing Rubber products with professional Technics, as well as Rubber Raw Materials Wholesales.

D: Delivery time—-20-30 days for mass production.

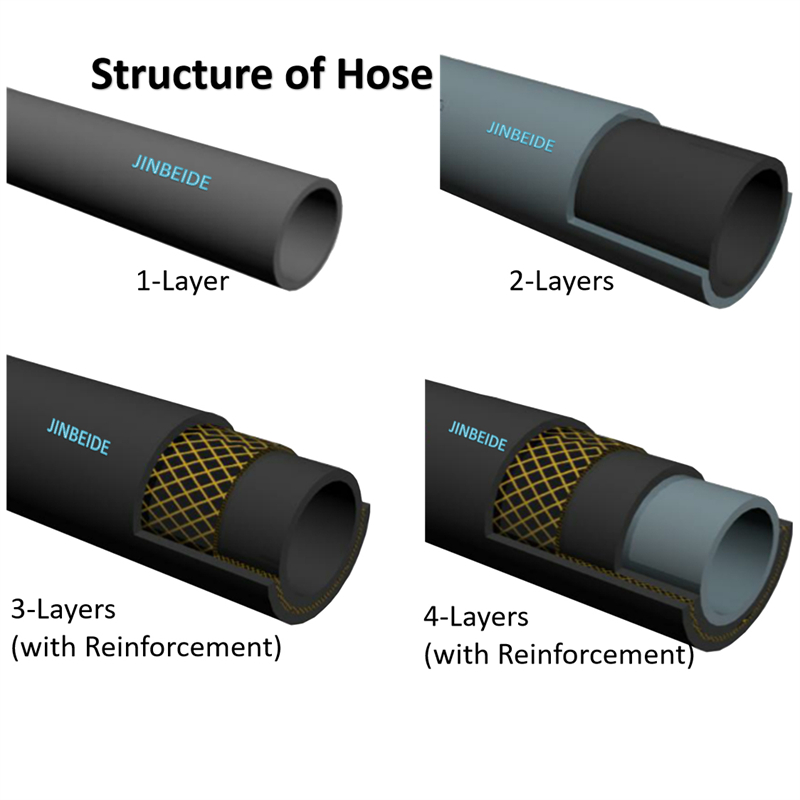

Structure of Hose

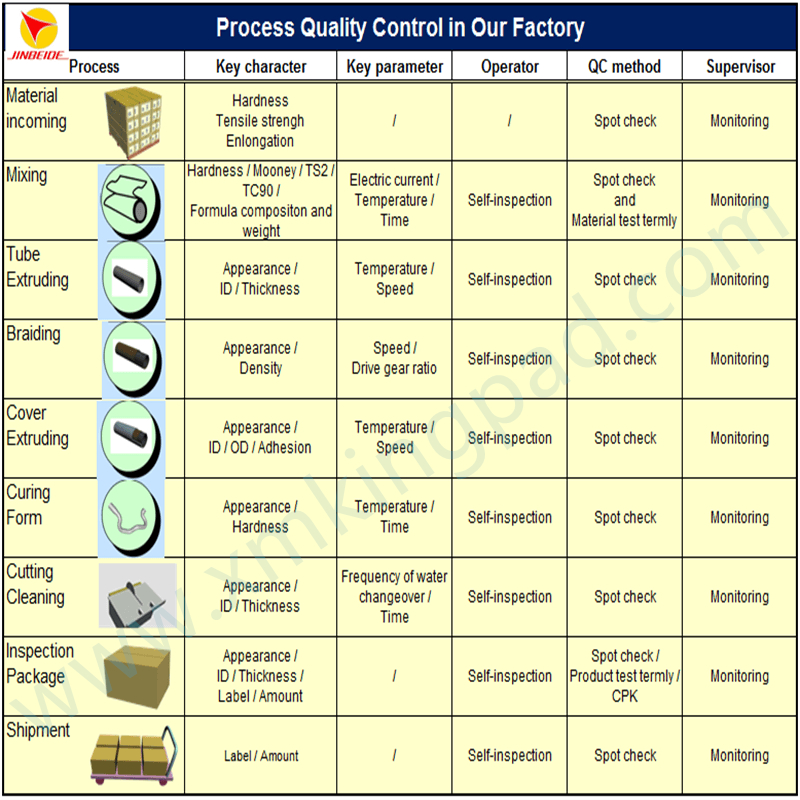

Process Of Quality Control

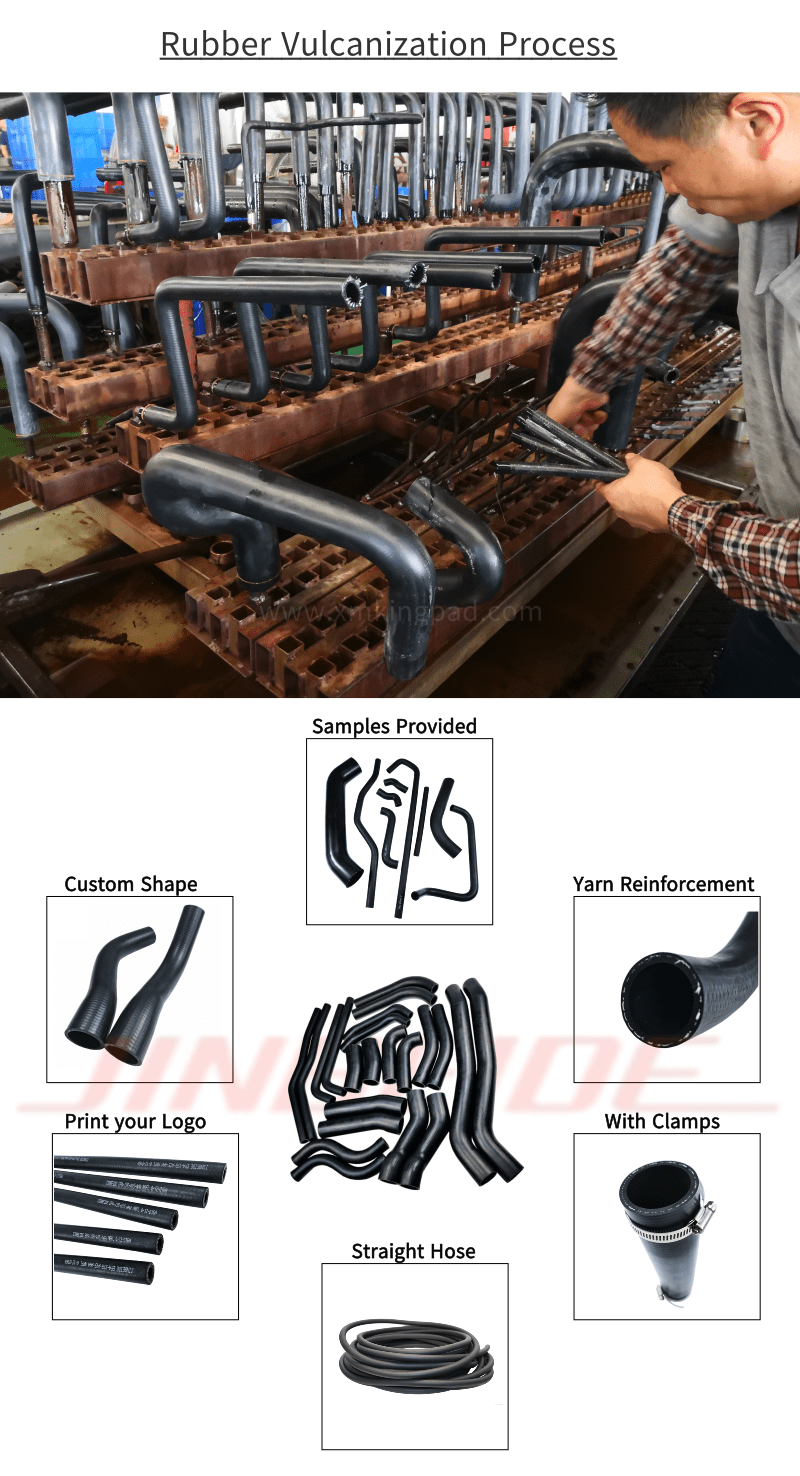

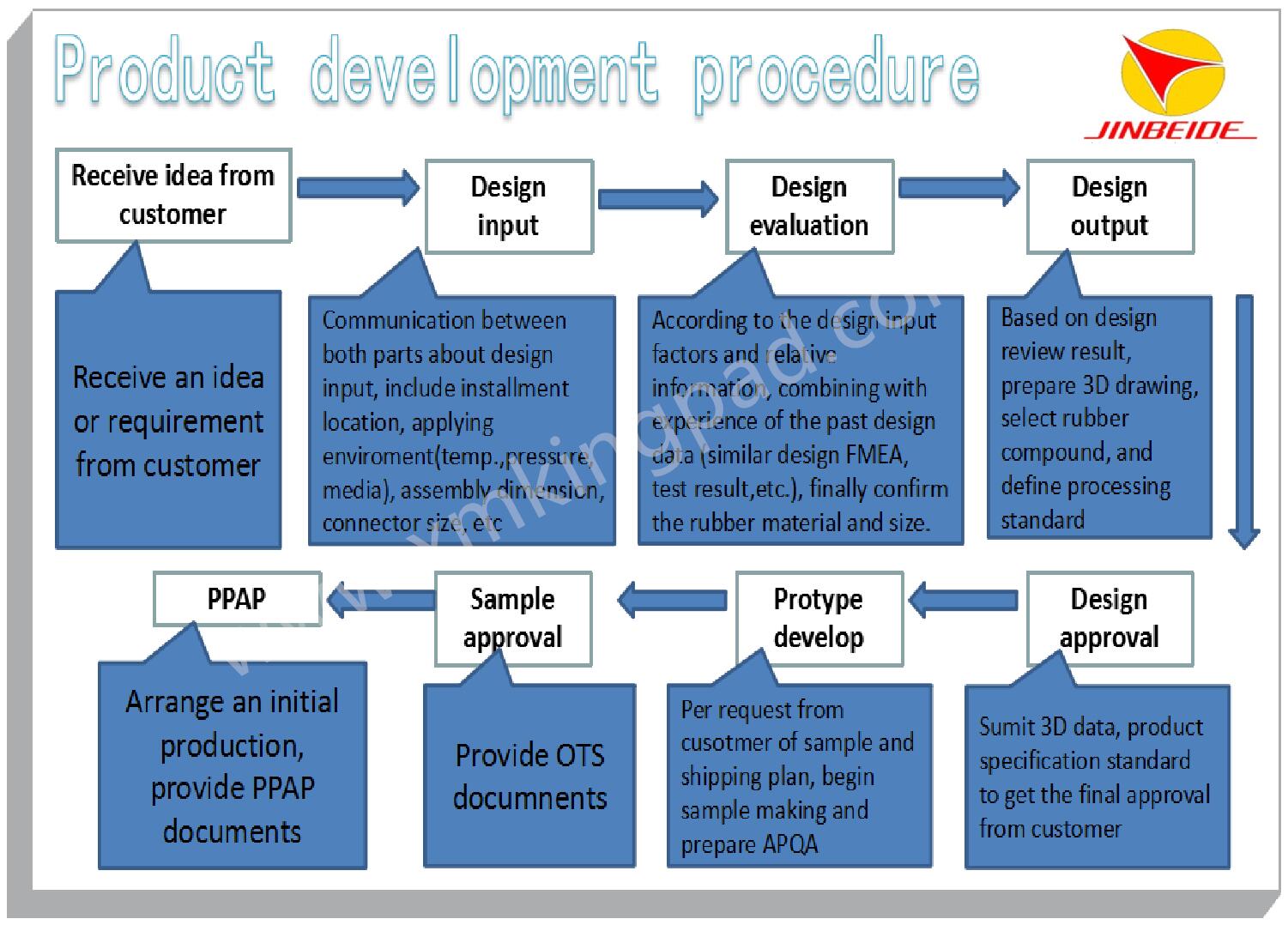

Process of Product Development

Products Collect

Packaging & Shipping